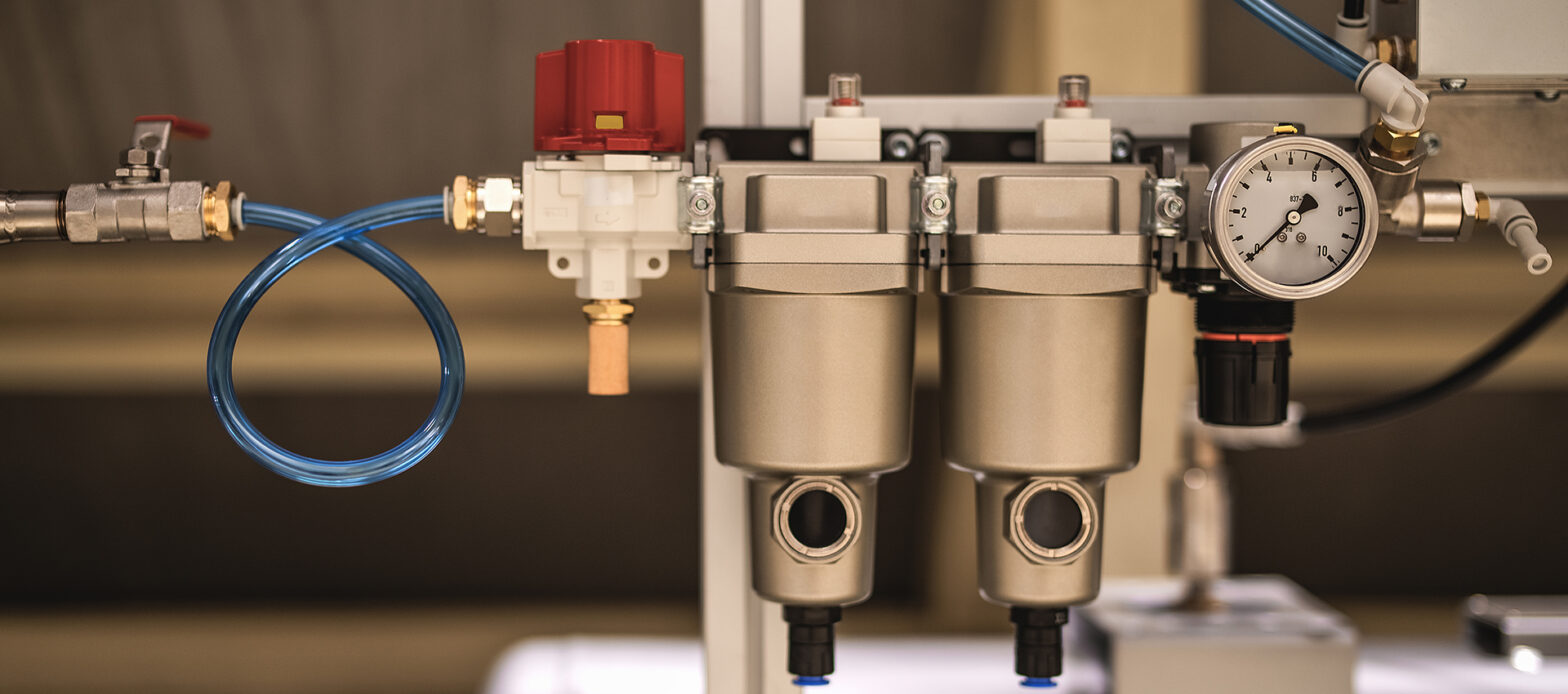

Compressed air systems are vital in industries ranging from manufacturing to healthcare. At the core of these systems are valves, which control, regulate, and direct the flow of compressed air to ensure optimal performance and safety. Understanding the types, functions, and importance of these valves can help businesses maintain efficiency and reduce operational costs.

Valves play a critical role in maintaining the flow and pressure of compressed air. They ensure that air is delivered to the right equipment at the correct pressure and volume. Additionally, valves protect systems from overpressure, prevent air loss, and enable seamless operation by managing airflow direction.

These valves allow air to flow in one direction, preventing backflow that could damage the compressor or other equipment.

Essential for preventing overpressure, these valves automatically release air when system pressure exceeds safe limits.

Also known as pressure control valves, these ensure consistent air pressure, which is crucial for maintaining the performance of sensitive equipment.

These electrically controlled valves automate airflow, making them ideal for systems requiring precise control.

These valves isolate sections of the system during maintenance, ensuring safety and preventing air leakage.

Efficient valve operation reduces air leakage, energy consumption, and downtime. Proper selection and maintenance of valves ensure that the compressed air system operates at peak efficiency, saving costs and extending equipment life.

At Oxymed, we provide a wide range of high-quality valves designed for reliability and efficiency in compressed air system. Our solutions cater to industries with the highest standards, ensuring safety and performance.

Invest in the right valves with Oxymed to enhance your compressed air system. Contact us today for expert advice and customized solutions.